| Hydronic System heat pumps and chillers |

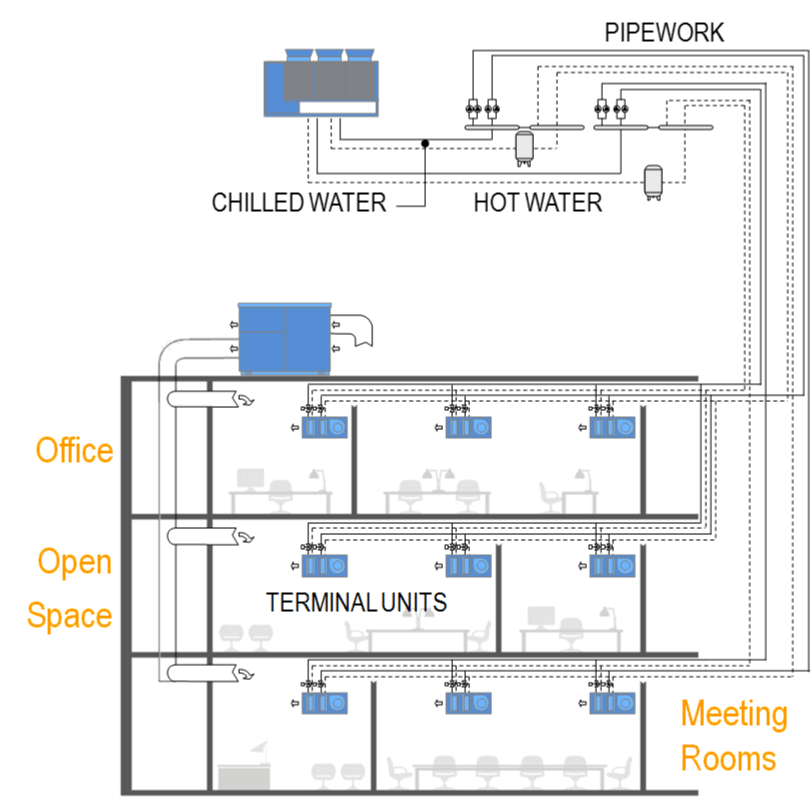

HOW DOES THE HYDRONIC SYSTEM WORK?

- In a hydronic system, the thermal and/or cooling energy for heating and/or air conditioning the rooms is produced by a liquid cooler (chiller / free-cooling) or by a heat pump (reversible / multifunction) with air or water condensation.

- The hot or cold water produced is then transferred through water piping to the indoor units (fan coils, radiant panels, radiators) in the various rooms.

AIR RENEWAL

- Air renewal in this type of system is usually carried out by an air handling unit supplied by a chiller (liquid cooler).

- Over the years, Clivet has developed autonomous air renewal solutions with an outdoor air heat pump with active thermodynamic recovery (heat recovery systems). Since they do not have to be supplied by a chiller, the system required to transfer the carrier fluids used to fulfil the fresh air load can be eliminated and the size and cost of thermal power and central cooling plants (chillers, heat pumps, boilers and components) can be reduced, as they only need to be sized to fulfil the building’s load.

SYSTEM MANAGEMENT

To maximise the system’s potential, Clivet has integrated optimisation and management systems: "Intelliplant".

Hydronic products and systems

FLEXIBILITY OF USE

The hydronic system is highly versatile and adapted for use with all types of terminals, from ventil-convectors to radiant panels and chilled beams systems. It is ideal also for critical applications such as operating rooms or food processing in shopping malls.

THE MOST KNOWN SYSTEM

The hydronic system is the most known and consolidated among the air conditioning systems. This simplifies the design, installation and maintenance.

SAFE AND UNLIMITED

The vector fluid is the water. This ensures safety, ecology, ease of maintenance, no limitation on the length and height of pipes.

ENERGY SAVING FLEXIBILITY

The system guarantees high energy efficiency, thanks to the Free-cooling function of air handling units, chillers and heat pumps.

This website uses cookies, including third party ones, to enable website operations, for statistics, to improve your navigation experience and personalise the communications sent to you. You may accept these cookies by clinking on “Accept all” or clicking on “Preferences" to personalise your choices. On closing the banner without accepting, the website will only use technical cookies (needed for the website to operate).

For more information, even on single cookies, please read our cookie policy and our privacy circular.

United Arab Emirates

United Arab Emirates  +971 (0) 4501 5840

+971 (0) 4501 5840  info@clivet.ae

info@clivet.ae  France

France  Germany

Germany  +49 40 325957-190

+49 40 325957-190  United Kingdom

United Kingdom  India

India  Russia

Russia  South East Europe

South East Europe