Mountain air that saves money

Pronvincia di Sondrio - Italia

Industria Farmaceutica

Sistema idronico

Anno 2020

CLIMATIZZAZIONE PER INDUSTRIA

Pharmaceutical industry

Technological application in industrial plant for process and HVAC use of liquid chiller with air source and freecooling exchanger

The challenge

In an industrial context located in the province of Sondrio, the client, an important industry in the medical sector, required a high power refrigeration unit suitable for production requirements with winter (use for process cooling) and summer (use for process cooling and HVAC) with high energy efficiency performance.

The solution

Taking into account the favourable climatic conditions of the installation area, located in the mountains of Valtellina, the design choice fell on a CLIVET unit with screw compressors and integrated on-board free cooling.

The CLIVET unit installed model WDAT-SL3 FC 360.2 EXC EN fully satisfied the client's requirements confirming the high design standards required, listed below:

- High seasonal cooling efficiency in compliance with the limits and calculation methods provided for by ErP regulations for process chillers (regulation eu 2016/2281):

- Required SEPR > 5.5; Clivet SEPR unit = 6.16;

- Nominal efficiency according to EN14511:2013 high:

- EER required > 3.0; Clivet EER unit = 3.14

- Minimum outside air temperature of the unit in operation:

- Required down to -15°C; Clivet unit suitable for operation and storage down to -20°C;

- Use of reduced GWP gas, in compliance with current environmental safety standards:

- Clivet unit supplied with R513a gas - GWP = 631 - non-flammable safety class A1;

- Given the variability of the process thermal loads to be disposed of, the cooling power had to be supplied in several partialisation steps:

- Clivet units with screw compressors able to modulate the cooling power delivered from 25% to 100% of the nominal power of the unit;

- Given the urban location and relative acoustic zoning plan of the area, the unit had to contain its sound level within the imposed limits:

- Sound power less than 97 dB(A): Clivet unit Sound power equal to 95 dB(A);

Given the insertion of the unit in an industrial area with the presence of moderately aggressive agents, the heat exchange batteries of the copper/aluminium unit were treated with a special acrylic coating in order to preserve their integrity over time.

The Clivet unit has also been set up in compliance with the requirements of the instrumental goods according to Industry 4.0 (law no. 160 - of 27 December 2019 - art. 1 paragraphs from no. 184 to no. 197) thanks to the construction equipment consisting of the on-board electronic control, the possibility of interconnection via TCP/IP network port and the Modbus serial communication card.

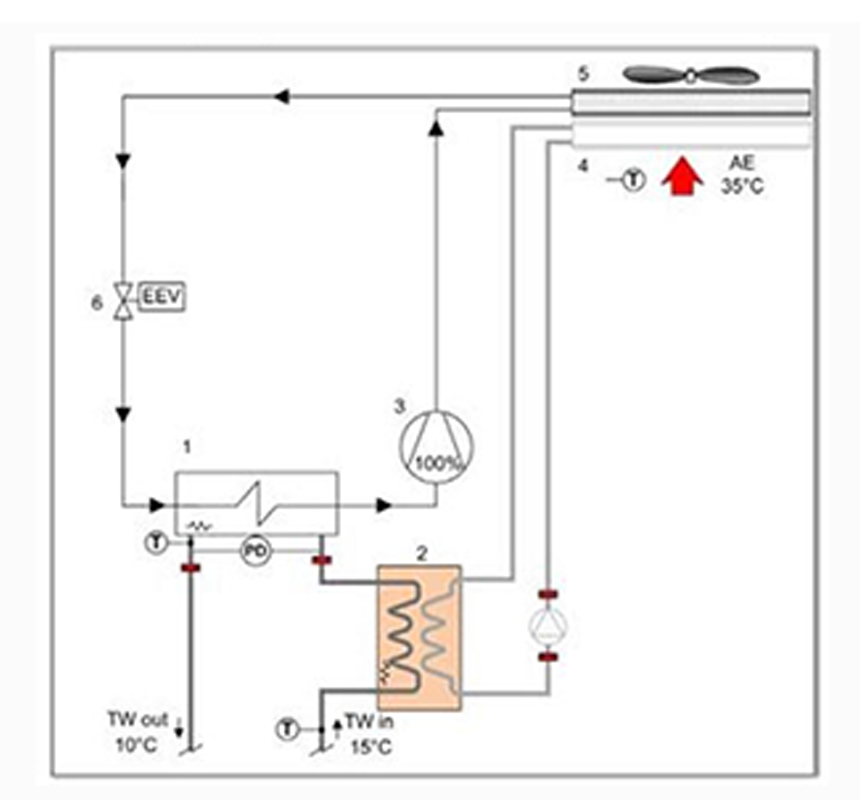

The Clivet unit is equipped with indirect freecooling: this configuration allows great savings on the management cost of the system in applications, such as the present one, which need chilled water for process use even during the winter season.

As can be seen from the internal construction diagram of the unit in indirect free cooling, an exchanger separates the hydraulic circuit of the system from the free cooling circuit.

The hydraulic system on the use side for process use DOES NOT need to be added with antifreeze liquids.

When the temperature of the external air is lower than the temperature of the water returning from the system, the CLIVET freecooling system recovers cold from the external environment and reduces the operation of the compressors until it is completely cancelled.

The higher the water temperature of the system, the greater the field of use of the free cooling system and therefore the energy saving: in the client's process application, the water supply for process use at 10°C was foreseen in winter, therefore more than favourable for the use of a free cooling system.

The operating simulations of the unit in winter operation for process use and chilled water produced at 10°C gave these results, considering an average winter temperature of the location of about 2°C:

At an outside temperature of +1.6°C the cooling requirements of the process system are met by free free cooling for 80% of the required cooling capacity!

At an outside temperature of +1.6 °C the electrical power consumption of the compressors is reduced to only 40% thanks to the energy-saving free cooling system.

The protagonists

Clivet Agency: Deltati

This website uses cookies, including third party ones, to enable website operations, for statistics, to improve your navigation experience and personalise the communications sent to you. You may accept these cookies by clinking on “Accept all” or clicking on “Preferences" to personalise your choices. On closing the banner without accepting, the website will only use technical cookies (needed for the website to operate).

For more information, even on single cookies, please read our cookie policy and our privacy circular.

United Arab Emirates

United Arab Emirates  +971 (0) 4501 5840

+971 (0) 4501 5840  info@clivet.ae

info@clivet.ae  France

France  Germany

Germany  +49 40 325957-190

+49 40 325957-190  United Kingdom

United Kingdom  India

India  Russia

Russia  South East Europe

South East Europe